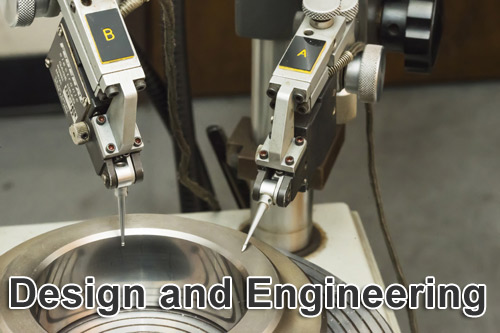

Whether you need a complete design for a new custom spindle concept or a modification to improve a single tool component of an existing application, Quality Spindle Services is here to help you. With an extensive background in spindle and tool component design and assembly and the latest in innovative engineering technology, our team will work directly with you to meet your specific requirements and provide custom solutions to improve your spindle and machine tool applications.

As part of our exclusive partnership with Parker Majestic/Penn United, we have immediate access to the complete history of Parker Majestic's spindle prints and engineering records. Additionally, Quality Spindle Services collaborates with Parker Majestic on concept and design of all new machine applications.

Contact us today and let us help you with your design and engineering needs for any model or brand of spindle.

Quality Partnership

Our highly skilled team cares about the quality and efficiency of your production lines. More than just a vendor or a supplier, we want to be your partner – offering manufacturing improvements, lower maintenance costs, and enhanced productivity.

Quality Mission

To use our extensive spindle technology and manufacturing experience to support our customers with the greatest value in spindle repair and spindle manufacturing services.

Quality Product and Service

Remanufacture of spindles and tool components to like new condition

Spindle Repair/Rebuilding Service – ALL MODELS AND BRANDS

Spindle Enhancements

Vibration Analysis

High Precision Grinding

CNC Machining

Tool Component Manufacturing

Engineering (reverse and new design)

Quality People

Our manufacturing team represents more than 125 years of spindle assembly and precision machining experience. Additionally, we are focusing on future innovation by training and educating the next generation of skilled manufacturing experts through our apprenticeship program.

Quality Resources

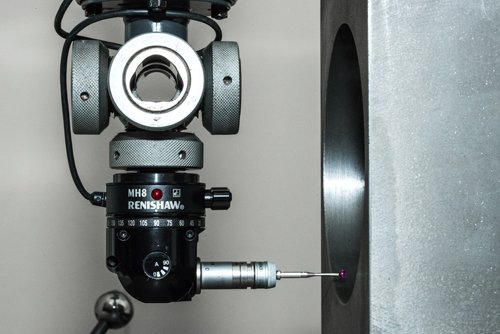

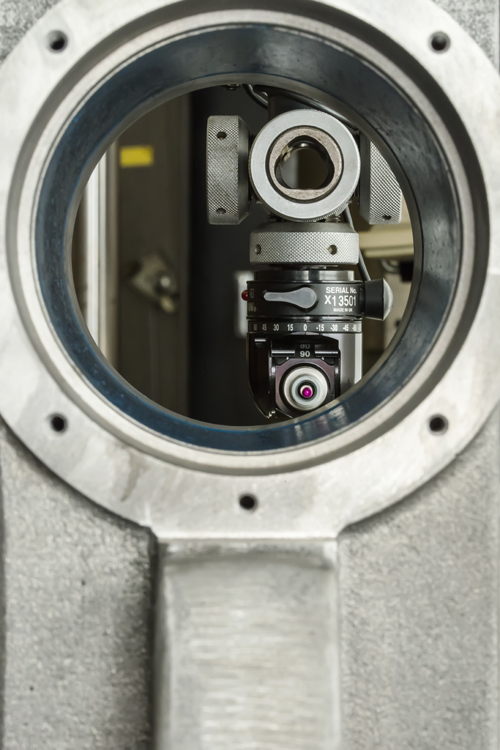

We are a complete design, manufacturing, assembly, and testing facility capable of high precision turning, milling, boring, and grinding - maintaining tight control over critical geometry and tolerances. Inspection and assembly are carried out in our temperature controlled clean rooms.

With more than 100 years of total spindle experience, our technicians have an extensive knowledge of a wide variety of spindles and have repaired most brands currently on the market. From high speed grinding spindles, to large robust milling spindles – and everything in between - we have seen it all!

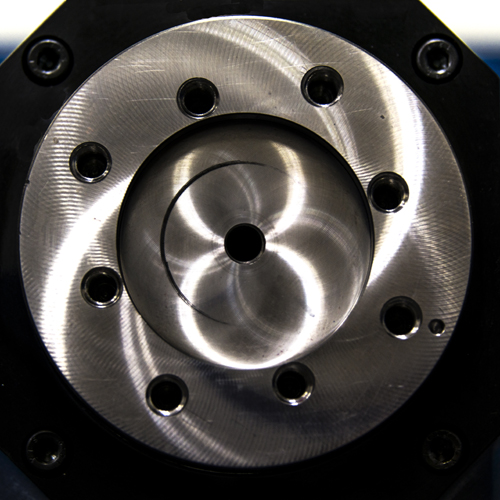

Using our engineering and precision machining capabilities we can develop and build the exact spindle to meet your specific requirements.

Whether you have an existing set of fully drawn prints or just a spindle idea, we want to partner with you to transform your concepts into the high quality machine components which will improve your processes.

Parker Majestic

We are the licensed manufacturer / repair facility for all Parker Majestic spindles. If your legacy model Parker Majestic spindle needs repair or improvement – send it our way!

In need of a newly manufactured replacement spindle for your Parker Majestic application? Call us! With a complete engineering history of Parker Majestic products and a manufacturing staff that is experienced in all Parker Majestic applications, we are your number one source for Parker Majestic spindles.